[ad_1]

London-centered design and style agency Bryden Wood, with places of work in Singapore, Barcelona, and Milan, will bolster its presence in the United States when it opens new headquarters in Boston this summer season.

Started in 1995, the firm now specializes in a price-oriented kit-of-elements “Platform” approach to design and style for production and assembly (DfMA). Bryden Wood’s North American growth is getting led by directors Jaimie Johnstone and Phil Langley, its head of international units and imaginative technologies, respectively.

In an job interview with BD+C final 7 days, Johnston said that Bryden Wood’s strategies to increase into the U.S. in 2020 have been postponed mainly because of the coronavirus pandemic. Prior to its relocating into Boston, Bryden Wooden had completed some function in the U.S. for the pharmaceutical business GlaxoSmithKline. Amid the AEC and assistance-company corporations at present teaming with Bryden Wood on industrial assignments in the U.S. are The Boldt Firm, Amazon Net Products and services, and DPR Development.

The timing of its enlargement, said Johnston, was determined by the gradual-relocating pace in the U.K. towards adopting offsite producing as an component of industrial design. “There have been pockets of excellence, but also a lot more of a emphasis on volumetric modular for homebuilding.” The opposite is happening in the U.S., he noticed, in which nonresidential builders and their AEC have been embracing prefabrication. Bryden Wood’s aim is to set up a North American source network for industrial elements.

Johnston pointed out that even though “a large amount of people” in the U.S. are prefabricating MEP parts, that competitive advantage “can be diluted more than time.” What Bryden Wood presents, he defined, is a merging of volumetric layout with production for much better and quicker outcomes.

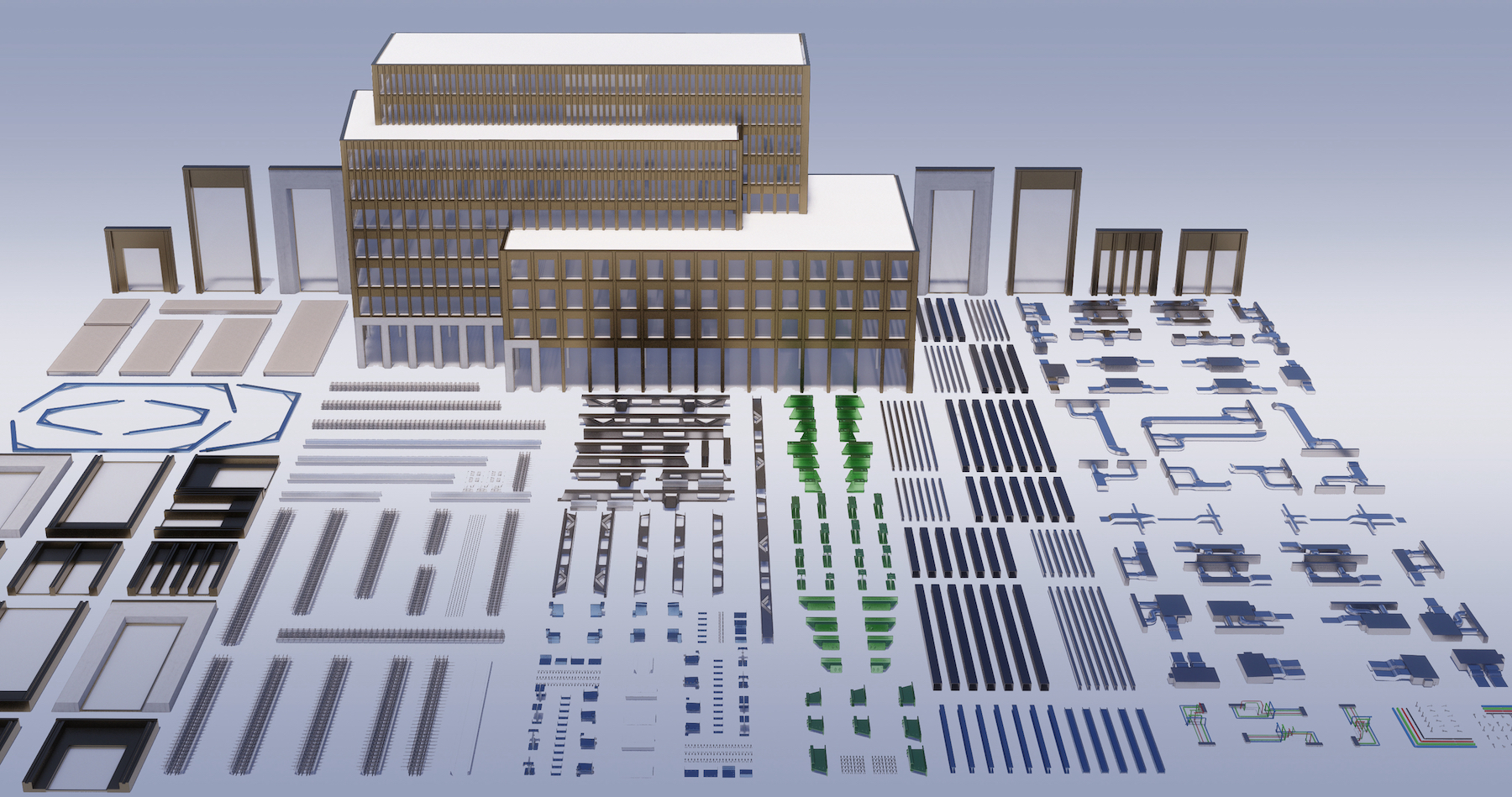

Bryden Wood’s System approach standardizes created factors that are produced offsite and assembled onsite, thus assuring larger certainty about schedules and budgets. Platforms also embed products reuse and reductions in carbon into early levels of design.

The agency is effective with tech shoppers to acquire design and style technologies these kinds of as “digital configurators” that rely on genetic algorithms to create 1000’s of design and style and engineering options for web-sites around the world. By developing options that allow appropriate ranges of repeatability in these building varieties as data facilities, without having sacrificing high-quality, “we’re serving to [clients] renovate their organizations,” said Johnston in a ready statement.

THE FORGE SHOWCASES System-Pushed Financial savings

The Forge has been a great deal faster and additional exact.

The initial big professional challenge remaining shipped making use of the System tactic to DfMA is The Forge, which topped out past December, and is scheduled for completion in the fourth quarter of this year. The Forge is comprised of two sustainably targeted nine-story industrial buildings—90,000 and 49,000 sf, respectively—in central London, constructed close to an obtainable courtyard. Its projected efficiencies consist of a nearly 20 % reduction in embodied carbon per square meter, a 36.4 p.c reduction in the substructure, and a 20.2 reduction in superstructure and façade products. Johnston stated that the buildings’ façade panels could be mounted in just 7½ minutes each individual, and with larger accuracy.

The Forge’s developer, Landsea, anticipates a 9.5 percent reduction in cash costs from this platform kit-of-sections technique. The Forge is also the U.K’s first net-zero strength job. The building workforce consists of a joint venture between the development companies Sir Robert McAlpine and Mace, and NG Bailey as the MEP engineer.

Johnston predicted Bryden Wood to concentrate its interest in North American on initiatives for health care, info facilities, pharma, and industrial, “wherever there’s a higher diploma of complexity and repetition.” On its web site, Bryden Wood stated it has been planning facts facilities considering that 1999, and has been delivering 30-40 % reductions in funds construct costs for each kilowatt, and an average 40 % improve in IT produce per sq. meter.

Scalability by way of industrialized development for these setting up styles is where by clients are most probably to gain from improvements in style and design and delivery, the company contended. Johnston also foresaw Bryden Wood undertaking a little bit more multifamily style and design in the U.S. than it does in just its dwelling sector.

A few decades ago, the business launched a absolutely free-to-use and open up-source housing style and design application called PRiSM that, it statements, provides together central and regional govt, investors, builders, and companies, with the purpose of driving improved productivity and high quality. The updated variation of PRiSM incorporates Bryden Wood’s Platforms approach to DfMA.

[ad_2]

Resource website link

More Stories

A Review of the Ford ‘Mustang’

Skills You Need to Restore a Classic Car

Five Steps for Buying Quality Used Cars